When you thought you had seen everything… Ron Koontz from Pine Island came out from nowhere. The sun reflecting in the hot varnish hit the camera lens like lightning, made it almost impossible to shoot! It took five years and 180 clamps. The fuel tank is entirely made out of birch. Those Americans. by Lars-Åke Krantz. Translation Ellen Kay Krantz.

The vehicle was a sparkling, glowing object consisting of 260 incredible well shaped wooden parts. He has taken craft and domestic art to another level.

The vehicle was a sparkling, glowing object consisting of 260 incredible well shaped wooden parts. He has taken craft and domestic art to another level.

Ron has a Bachelor degree in arts and crafts.

Ron has a Bachelor degree in arts and crafts.

He got the idea for the car back in 1970 but then the gas crisis struck in 1972 and the believed the hotrod area would die out.

Then rang the wedding bells, two kids soon came along, two houses and thereafter he started building boats. In 1993 he moved to the sun and in 1997 he felt like:

– Well, I’m goanna go ahead and build me that car.

Ron lives exactly 23 steps from the water. A pelican is hanging out on the boat jetty. The heat is intensive and we crouch behind primitive sun screens. His boats smell like an island in the south pacific. It’s cooler in the shop. The shop has a 16 feet high roof where the scent of wood fills every cubic inch. I receive all the 120 points of bachelor degree at once – In English.

Click on the picks bud.

The method is called strip planking. The material is Honduras mahogany.

The method is called strip planking. The material is Honduras mahogany.

One lap a day of sawing, pressing and fitting.

The steel frame to the rod is taking shape and the strip planking is being made after this gig. Hood and sides were simultaneously glued and then sawed apart. Don spent five years on this project.

The steel frame to the rod is taking shape and the strip planking is being made after this gig. Hood and sides were simultaneously glued and then sawed apart. Don spent five years on this project.

Don didn’t hold anything back. He hit the brakes quite late and turned the wheels to let them struggle on the hard asphalt. The wooden body looked like it had been glass framed.

The gluing process is a crock pot of 20 years of experience in making propellers, ice yachts and boats.

The gluing process is a crock pot of 20 years of experience in making propellers, ice yachts and boats.

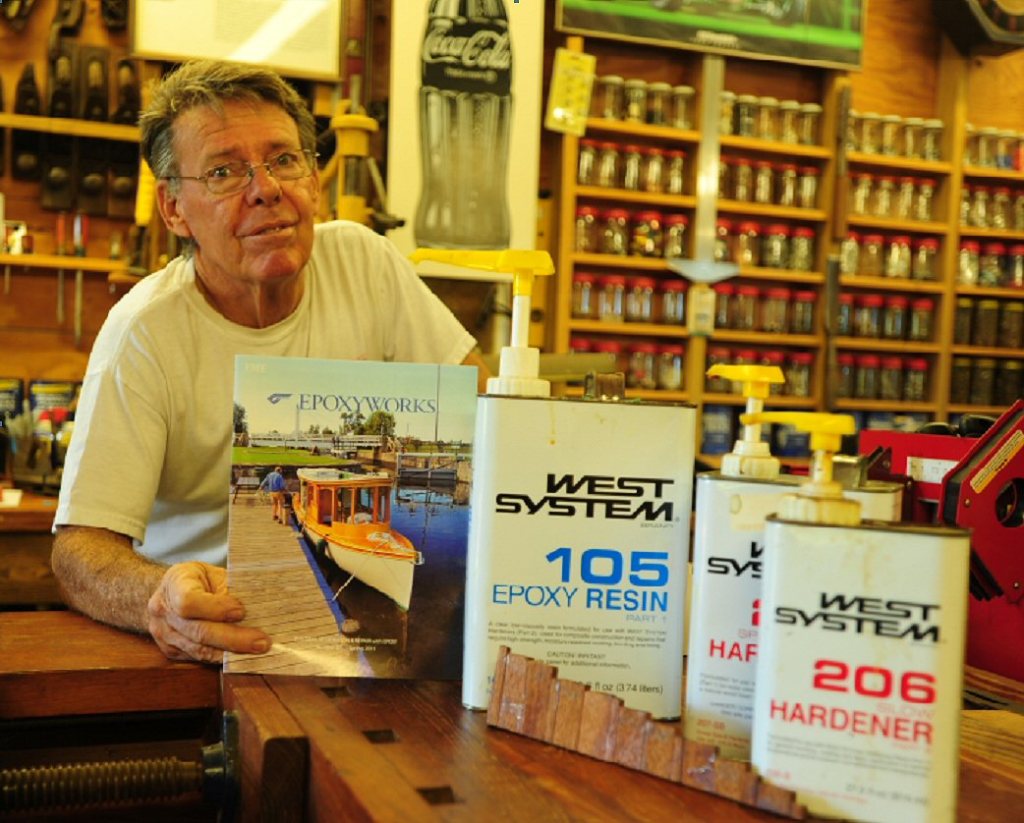

Cross piled veneer and Ron’s own Epoxy recipe with different hardeners for different purposes has made it possible.

– It’s stronger than fiberglass, both in sustainability and durability, he says.

Ron started in 1997 with making the steel frame. Yeah, of course he welds as well, even though he first started with making a wooden model!

Ron started in 1997 with making the steel frame. Yeah, of course he welds as well, even though he first started with making a wooden model!

A Chevrolet Caprice had the honor of donating a 305 HO small block, th700 and a LSD rear axle with 3,08:1.

A Chevrolet Caprice had the honor of donating a 305 HO small block, th700 and a LSD rear axle with 3,08:1.

After a coat of spray-can paint the chassis was standing on all four.

Yeah, then it all started. Two ribs in press in the morning and then two after strains during the day resulted in the rear corners. Every rib had its own radius to make the body expand further up. Dry time for the Epoxy is three hours but then the wood needs some sawing as well. Ron built the car rib by rib. The photos don’t do the car justice. All “scratches” and spots works as reflexes in the shiny epoxy varnish. There is not a mark on the car. The depth is amazing.

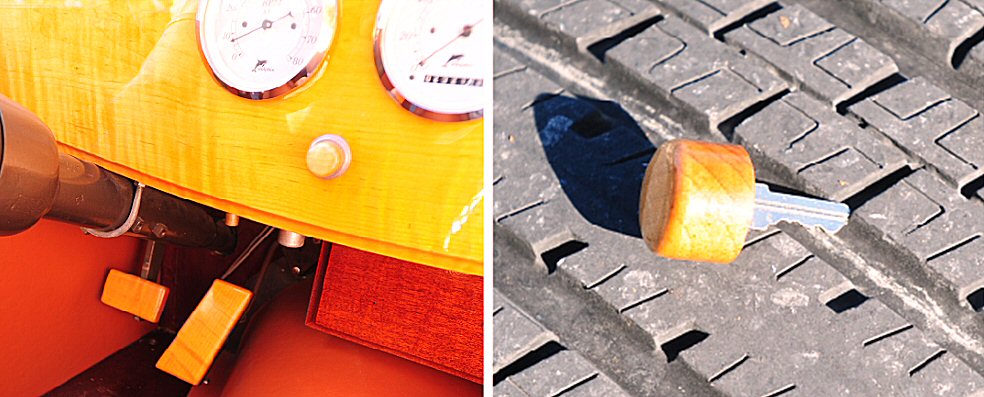

180 clamps where in the shop and most of them were put to work duting the project. The dash is made by “curly maples”. He also wanted the chairs to be by another tree and so he chose cypress.

He builds the entire vehicle without blueprints or images, the man that built boats and canoes for years. The bottle hanging in the work shop in a huge format wasn’t just an ad sign. Dan painted it as a school project.

He builds the entire vehicle without blueprints or images, the man that built boats and canoes for years. The bottle hanging in the work shop in a huge format wasn’t just an ad sign. Dan painted it as a school project.

The rod has double fuel tanks embedded in-between the frame beams in the rear.

– For these ones I went with southern yellow pine, Ron simply says.

– B-but it’s supposed to hold tight against gasoline and pine isn’t exactly the most massive of woods, I said trying to sound intelligent.

– It’s not necessary either, he said. The tanks were easy to make. The grill was more difficult. It has 67 separate wooden pieces.

A gas tank in pine?! Almost getting crazy mad of how crazy good people are.

67 parts. Furniture wood work in birch and mahogany. And then wood that always moves around expands and is very dynamic. It isn’t weld-able either. Awesome.

We walk down to the boat pier. He has his own sailboat winched. The construction is of course self made. It’s fully possible to buy one but Don Koontz created a design of his own. He built the boat himself too.

– Our family has had some good times in this one, he says and I can’t keep from staring at the placement of the huge boat.

– What, oh that, well, but it felt natural to put it there and it’s working for us, Don says, simply.

We take a ride in the woody and I’m expecting some rattle and noise but I hear nothing. The frame is short and stiff and the body solid. A strange feeling. It’s like doing 60 mph in drawer. The finish is incredible after 12 years.

– Well, the Epoxy didn’t do so well in the sun. It got milky so I had to grind it all down after a year or two and remix it but now it’s pretty solid.

The guy in shorts is 68. The wind is blowing through his hair. He’s late on the breaks as he turns on to a small road with the wheels seeking grip and he smiles.

-I’ve worked with cars for 60 years and with boats in 30. This is my life, he says with the sun shining in his face.

Torpedo wall in wood of course. Tight and warm but without discoloration.

Dan Koontz hasn’t heard about anyone doing what he has done.

Dan Koontz hasn’t heard about anyone doing what he has done.

The rod consists of 230 wooden parts in total. In a couple of seconds Don pulled out the dash and showed the electric system. Wonder if he’s got secret compartments too – like in that ancient furniture?

The pedals, as well as the key are made of wood. Underneath the panel was a wooden box with a sunken tool cassette. Behind it was the battery. Nothing was missing in the little rod. That’s some crazy craft work.

In the yard ice cold refreshments are served and the channel’s still water forms a soothing atmosphere at the Koontz’. Don gets weary after halfway into the drink.

In the yard ice cold refreshments are served and the channel’s still water forms a soothing atmosphere at the Koontz’. Don gets weary after halfway into the drink.

– You wanna’ see my next project, he asks?

Up on our feet with sticky hands we open work shop door number two. In there we find canoes, wagons and a teardrop wagon, all in wood of course.

Something else is in there. The old man has done it again! He has started on a new car. This time one with roof. Don talks but I don’t listen. The gigantic car is a wood-shock inside-out but my notepad is full and all the impressions are overwhelming.

Maybe we should return to Pine Island and Don in the near future when the project is finished to show our valuable readers of Worldkustom.

Until then. -So long.

Vilket enastående bygge,och lönnfack får ju en viss innebörd

Helt makalöst och hur grymt som helst! Eftersom jag själv har fuskat i det mesta även trä så vet jag att där går det inte att fuska eller spackla om träytan ska vara synlig! Helt grymt arbete och tålamodskravande.

Gunnar

Hi, very good article. I am a Kiwi boatbuilder and thinking of building a wooden roadster for everyday use.

Your English is cute. Very entertaining!

Bring us more timber cars please.

Stuart Vivash

Aukland.